Brighton NC Manufacturing Solutions

Michigan's Leading CNC Machining Company

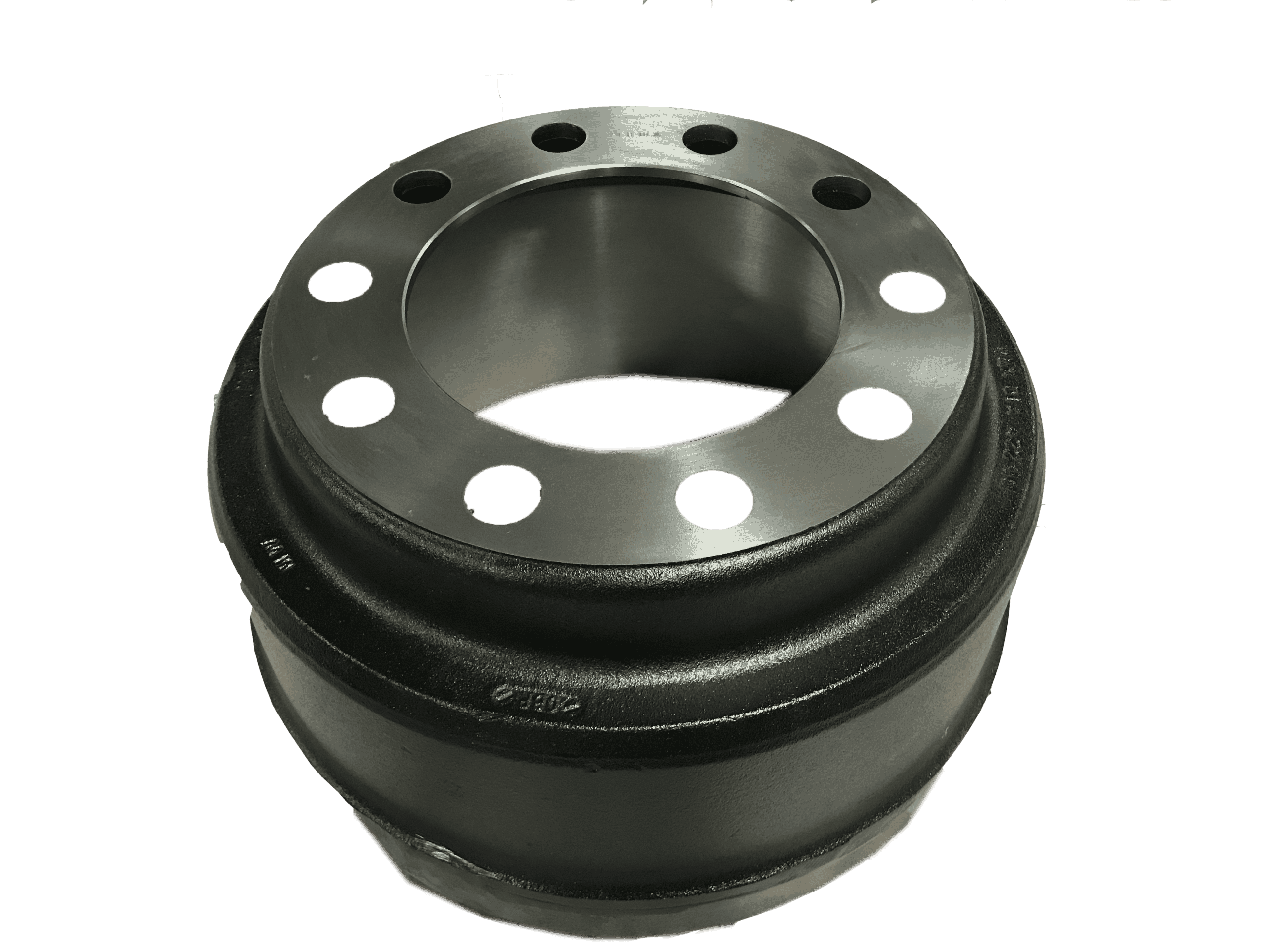

Our capabilities

Brighton NC Provides:

- Milling - up to 84"

- Turning - up to 45" diameter and 18' between centers

- Grind: Rotary surface, CNC OD/ID, Centerless OD

- Assembly, Leak test, Balance, Thread Forming

Our Core Competencies are procurement of foundry tooling, castings and forgings. The Manufacturing/Engineering for design, build and implementation of fixtures and processes. Electronic data interchange(EDI).

Our sourcing is global with castings from the US, UK, Canada, Germany, Switzerland, Columbia, Brazil and China. Ring Gears from India, Algeria and Spain. Perishable tooling from the US, Israel, Germany, Japan and Canada.

CNC Machining Centers: 42

84”x72”x72”

Table length: 650 to 1800mm

Tool capacity: 20 to 40

Taper: 40 and 50

Industries served

Since 1965, Brighton NC has been providing machining solutions to customers in a wide range of industries. Every customer has unique needs and each industry has specific standards. We recognize that and deliver industry-specific solutions. It’s because of our investment in state-of-the-art machining technology, including vertical and horizontal machine centers and lathes, that we can produce quality products for our customers in the following industries:

About Us

Brighton NC Machine became known as a machining company, driven by a machinist, Jack Clausnitzer. Jack insisted that machining fundamentals were learned and passed on to all employees. Many of the people who have benefitted from this training have been with the company nearly 40 years. Over the years, BNC added many other very talented people who have shown continued dedication to their profession and the company's success. These people are BNC's foundation and our primary competitive advantage.

Our core competencies are procurement of foundry tooling, castings and forgings as well as manufacturing/engineering for design, build and implementation of fixtures and processes. We also have experience in Electronic data interchange(EDI) and other disciplines. But what makes us stand out above the rest is the in-house training we provide for our machinists, providing top quality work in a timely manner that you won't get from any other CNC machining manufacturer.

Our Clients

We are proud to have worked with Ford on numerous occasions building out the proper automotive parts at our shop in Michigan.

Our Certifications

Brighton NC takes pride in the certifications that we've accomplished procuring over the years. These certifications provide the necessary quality assurance in every product that is manufactured in our shop, for your peace of mind as the customer.